OSB sheets: thickness and dimensions, prices and material properties

Modern building materials include OSB sheets. The thickness and dimensions, prices of these plates allow them to be widely used. It is in demand in the construction of partitions, battens for roof structures, as well as in the cladding and construction of walls. The technical characteristics of these boards are better than those of Fiberboard and chipboard. Before purchasing a suitable option, it is worth understanding the existing classifications, characteristics, and also the scope of the sheets.

The content of the article

Varieties of OSB sheets and manufacturing techniques

OSB is an oriented strand board. To create it, chips and shavings are used. Several layers of such sawdust are pressed in mutually perpendicular directions. This adds a resin-based polymer material.

OSB sheets are of different types. In this case, the thickness and dimensions, the prices of the material may differ. The following varieties are distinguished:

- OSB -1 can be used in low humidity conditions. Such plates are used to create furniture;

- OSB - 2 is used for the construction of internal supporting structures. It should also be used only in dry rooms;

- when creating capital partitions and other supporting structures, even in conditions of high humidity, OSB-3 is used, the dimensions of the sheet may differ;

- the most durable and moisture resistant fabric is OSB - 4.

Helpful information! Most often, OSB-3 canvases are used, which are characterized by versatility. They can be used in various types of construction work.

Characteristics and dimensions

A similar material has been used for many years in European countries and in America, due to its special properties:

- canvases differ in convenient standard sizes;

- characterized by ease of processing and use. When sawing, the blade will not split;

- possesses strength, can withstand increased loads. The plate is stiff, which allows you to mount any fasteners in it;

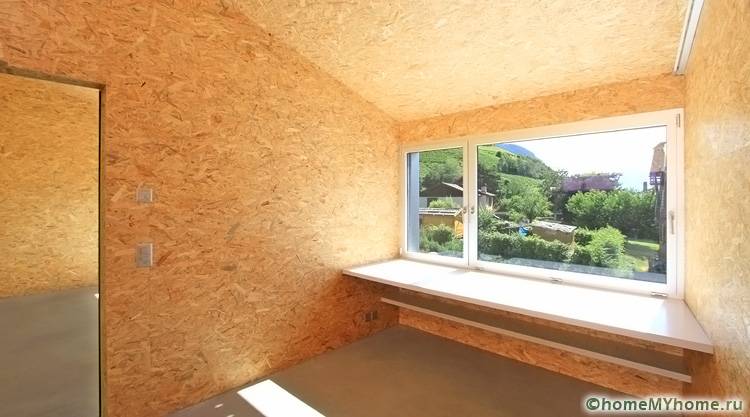

- after installation, the surface can be painted or other types of finishes can be applied;

- does not delaminate, voids and knots are not formed;

- environmentally friendly material, it contains a minimum amount of formaldehyde resins;

- it has excellent soundproof and heat-insulating qualities;

- characterized by resistance to mechanical damage and various chemicals;

- has low weight and low cost.

Useful advice! Before applying the plaster to the slab, prime and level the surface.

Related article:

Plywood sheet thickness and dimensions with prices. In a separate publication, you will find detailed information on the types of plywood, their standard sizes, applications and prices.

Areas of use of plates

In many areas of work, the use of OSB sheets is practiced. Thickness and dimensions, prices of material influence the choice for certain purposes. Plates can be used not only in the construction of various buildings, but also in the production of packaging containers, furniture or interior decoration of various types of transport.

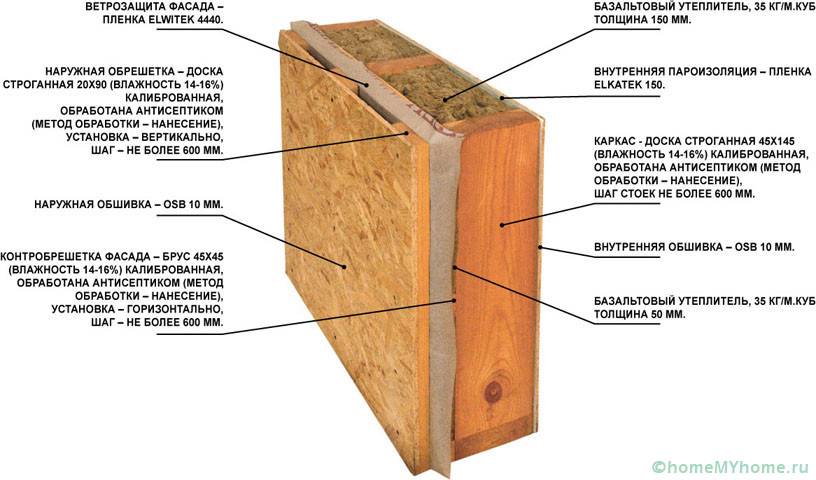

Plates are especially often used for the following works:

- installation of partitions and ceilings. At the same time, slabs with a thickness of 10-12 mm are in demand;

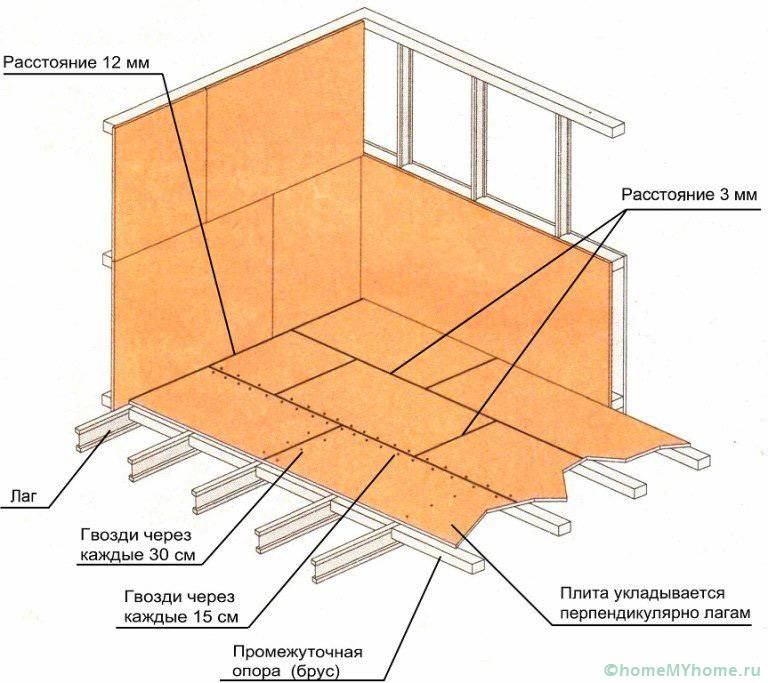

- for finishing the floor, while the canvases are laid perpendicular to the logs, the thickness of the plates should be at least 18-22 mm;

- roof lathing is made of slabs. In this case, moisture resistant OSB is used. The dimensions of the sheet and the price, as well as the thickness of the material, are carefully selected. From above, the roof is equipped with metal tiles, slate or roll materials;

- often used for temporary fences. Plates can be used for fences or protective structures.

Useful advice! Before sheathe the walls with OSB material, you need to install metal profiles. The battens should be installed at 40 cm intervals.

Related article:

SIP panels: what is it? Why is this material so popular? What are its advantages? How much is a house made of SIP panels? More details in a separate review.

How to choose the right OSB sheets: thickness and dimensions, prices

The cost of these plates will depend on the size of the sheets, thickness, and also on the selected manufacturer. It is not worth purchasing slabs of a larger size and thickness than required. This will lead to a lot of waste. It is better to choose a material of suitable dimensions and a trusted manufacturer.

Having studied the range of similar products, you can make sure that this building material will allow you to perform various types of work.

Helpful information! Beginners can purchase slabs in standard sizes. This will make it easy to calculate the required amount of material, as well as additionally cut the required canvases.

Overview of manufacturers and prices

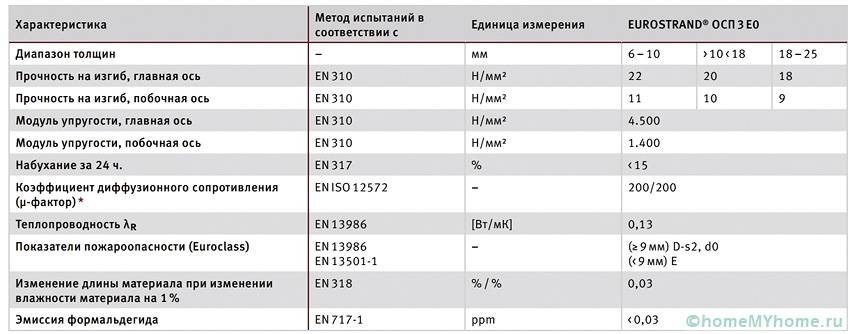

The table shows major manufacturers, as well as standard sizes, costs and main characteristics of materials.

| Manufacturer | Dimensions, mm | Specifications | Average cost, rub. |

|---|---|---|---|

| Novovyatsk Ski Factory (Russia) | 1250x2500x9 1250x2500x12 1250x2500x18 600x1250x9 600x2500x9 | No formaldehyde odor. The density is 70 kg per cubic meter. | 560 790 990 125 235 |

| Hillman (Russia) | 2500x1250x9 | In production, large birch shavings are used, which allows achieving high quality standards and excellent physical and mechanical properties. | 510 |

| Norbord (USA, Canada, Belgium) | 1220x2440, 1250x2500, 1250x2800 thickness - 8,9,10,12,15,18,22,25,32 mm | Low moisture absorption, resistance to various weather conditions and maximum rigidity. | 525 - 1 900 |

| EGGER (Germany) | 2500х1250х9 2500х1250х12 | The raw material is coniferous wood, which is flexible, lightweight and biologically resistant. Increased strength to impact, splitting, deformation | 910 1290 |

You can choose different OSB plywood. Sheet dimensions and price, thickness will depend on specific manufacturers. The color palette can range from light yellowish to brown. The shade is influenced by the breed used, the pressing technology and the types of resins used.

Helpful hints

Plates up to 16 mm thick are used for wall decoration, as a base for soft roofing, as well as for flooring.

Sheets with a thickness of more than 16 mm can be used under significant loads. A floor is laid on such a material, and roof structures of the supporting type are also produced. For processing OSB, tools with carbide tips, cutters, saws and drills are used.

There are certain peculiarities when working with such material:

- the feed rate will be lower than when processing wood;

- it is better to fix the material with spiral or ring nails, it is better not to take others;

- when installing OSB in load-bearing elements, you need to select a material that will not rust;

- when installing plates, it is necessary to leave gaps for insurance.

Such material as OSB sheets facilitates the performance of any construction work. Thickness and dimensions, prices are selected depending on the planned work.It should be borne in mind that the installation of the plates is not done without preliminary preparation. When arranging floor coverings, logs are mounted. For roof installation using OSB, a special lathing is created. Wall cladding requires a frame for which the profiles are applied.

Correctly using OSB boards, you can significantly facilitate construction work. This material has higher quality indicators than many alternatives.